About ECONYL®

ECONYL® regenerated nylon is a sustainable solution that addresses the issue of nylon waste, which would otherwise contribute to environmental pollution. This innovative material is virtually indistinguishable from brand new nylon and possesses the unique capability to undergo recycling, regeneration, and remolding processes repeatedly.

Every 10,000 tons of ECONYL® raw material is the equivalent to saving 70,000 barrels of crude oil and avoiding 65,100 tonnes of CO2 emissions.

Waste Sources

FISHING NETS FROM AQUACULTURE, FISH INDUSTRY AND GHOST NETS

This comprises of mainly nets from the aquaculture and fishing industries and, in a smaller quantity, nets recovered through the Healthy Seas foundation.

The purpose of the initiative is not only to clean the oceans and seas of marine litter such as derelict fishnets responsible for the needless death of marine animals but also to prevent them from ending up in the seas and raise public awareness.

The fishing nets recovered in collection points from the sea bed by volunteer divers are first cleaned and sorted and then, those suitable for recycling (made of Nylon 6 and not too ruined), sent to Aquafil’s Slovenian regeneration plant. Not all the marine litter collected and rescued by the divers can be regenerated into brand new ECONYL® nylon. Indeed, some stuff retrieved during diving activities are made out of different materials. As we deal with Nylon 6 waste only, the rest of the collected trash is sent to different streams or used to produce energy.

OLD CARPETS DESTINED FOR LANDFILL

Each year in the U.S., 4 billion pounds of carpet is discarded in landfills.

Aquafil Group is committed to help reduce this waste by implementing a closed-loop supply chain where carpets are recycled.

Aquafil has two carpet recycling facilities — in Phoenix and Woodland, CA — that can each process up to 36 million pounds of carpet annually and break old carpets down into three main components: polypropylene (PP), Nylon 6 and calcium carbonate. Special Take Back Projects

1. Nylon 6 is sent to the ECONYL® Regeneration Process in Slovenia with other waste, like reclaimed fishing nets or textile scraps, to make ECONYL® nylon for infinite uses.

2. Polypropylene (mainly used for the backing of carpets) goes into injection-molding production.

3. Calcium carbonate (used to stabilize the carpet) goes into road construction and concrete.

PRE-CONSUMER WASTE

Pre-consumer waste comes from industrial processes such as plastic components, industrial waste and fabric scraps.

SPECIAL TAKE-BACK INITIATIVES

An international network structured around recovering materials at end of use, based on partnerships with institutions, organisations, private and public associations and companies. This system allows Aquafil to collect quantities of waste for regeneration into ECONYL® yarn. Examples of this effort are represented by special take back projects in collaboration with different brands such as Napapijri, Speedo and Gucci.

Synthetic fibres such as Lycra, polyester and nylon release microfibres when put into a washing machine. For this reason we always recommend using a microplastic wash bag.

ECONYL® is recycled so it has a positive impact on the earth, however being a synthetic it still releases microfibres. We're working on adding microfibre wash bag to our range but in the meantime, we love the one from Guppy Friend!

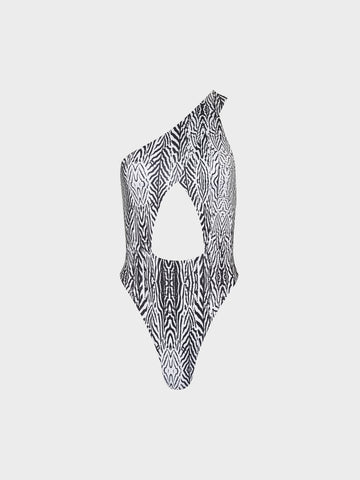

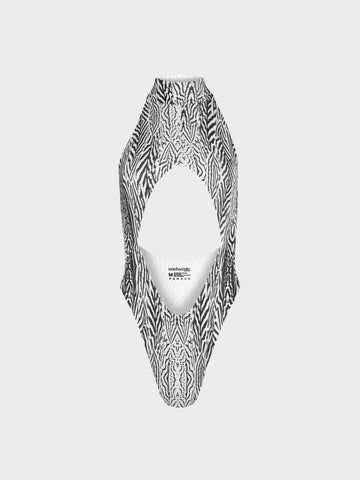

Shop ECONYL®

- 特色

- 畅销

- 按字母顺序排序,A-Z

- 按字母顺序排序,Z-A

- 价格,从低到高

- 价格,从高到低

- 日期,从旧到新

- 日期,从新到旧